158" Sawmill Blades

- 2 Circular Blades. 1 Adjustable Blade.

Manufactured from carbon steel, SilverTip sawmill blades can be used on both portable and industrial sawmills and is also suitable for horizontal resaws. Carbon is the most common steel used in narrow-band sawing and can be resharpened, but typically not as often as a blade made with high-alloy steel.

- Width 1", 1.125", 1.25", 1.5", 1.75", 2", 3"

- Thickness .035, .038, .042, .045, .050, .055

- Softer than "high-alloy steel"

Typically not resharpened on horizontal resaws using narrow widths (1", 1.125")

Sawmill Blade Selection Guide

Wood-Mizer Sawmill Blades

From green softwoods to abrasive hardwoods, Wood-Mizer manufactures an extensive range of sawmill blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and alloy for any type of sawing or resawing application. Each Wood-Mizer sawmill blade tooth is precisely set by computer-controlled equipment and completely profile ground tip to tip using super abrasive CBN grinding technology to ensure the highest quality blade performance. Made in the USA, all Wood-Mizer blades are quality checked for performance throughout more than 100 tests and inspections from the selection of raw materials to the final grind. Count on Wood-Mizer sawmill and resaw bandsaw blades for unmatched quality, accuracy, and performance across the board.

DoubleHard’s original blade material is manufactured from high-alloy steel and is designed for portable and industrial sawmill equipment. With the combination of harder high-alloy steel and induction hardened teeth, DoubleHard blades deliver twice the toughness and twice the sharp life compared to standard carbon blades and can be resharpened several times with a CBN grinding wheel. DoubleHard sawmill blades are durable all-purpose blades for sawing softwoods, hardwoods, knotty woods, and frozen woods.

Manufactured from carbon steel, SilverTip blades can be used on both portable and industrial sawmills and is also suitable for horizontal resaws. Carbon is the most common steel used in narrow-band sawing and can be resharpened with a CBN grinding wheel, but typically not as often as a blade made with harder high-alloy steel like DoubleHard blades. SilverTip sawmill blades are ideal for economical sawing, primary and secondary breakdown as well as for high volume sawing environments.

BiMetal is made from high-alloy two piece steel with a wire-welded, hardened tooth tip. Generally used for primary breakdown sawing in portable or industrial sawmill operations, BiMetal blades hold a sharpened edge up to three times longer than carbon blades and can be resharpened multiple times with a CBN grinding wheel. BiMetal sawmill blades offer a longer sawing sharp life than most carbon and high-alloy blades and are engineered for production sawing environments.

RazorTip Carbide blades utilize a very hard triple chip tooth configuration with an alternating carbide-tipped raker tooth that can withstand the hardest of hardwoods and provide a very smooth finish. A diamond grinding wheel is required for sharpening due to the extreme hardness of the carbide material. RazorTip Carbide sawmill blades are tough and stay sharper longer in the most difficult sawing conditions such as tropical hardwoods, kiln dried lumber, engineered wood, and more abrasive materials.

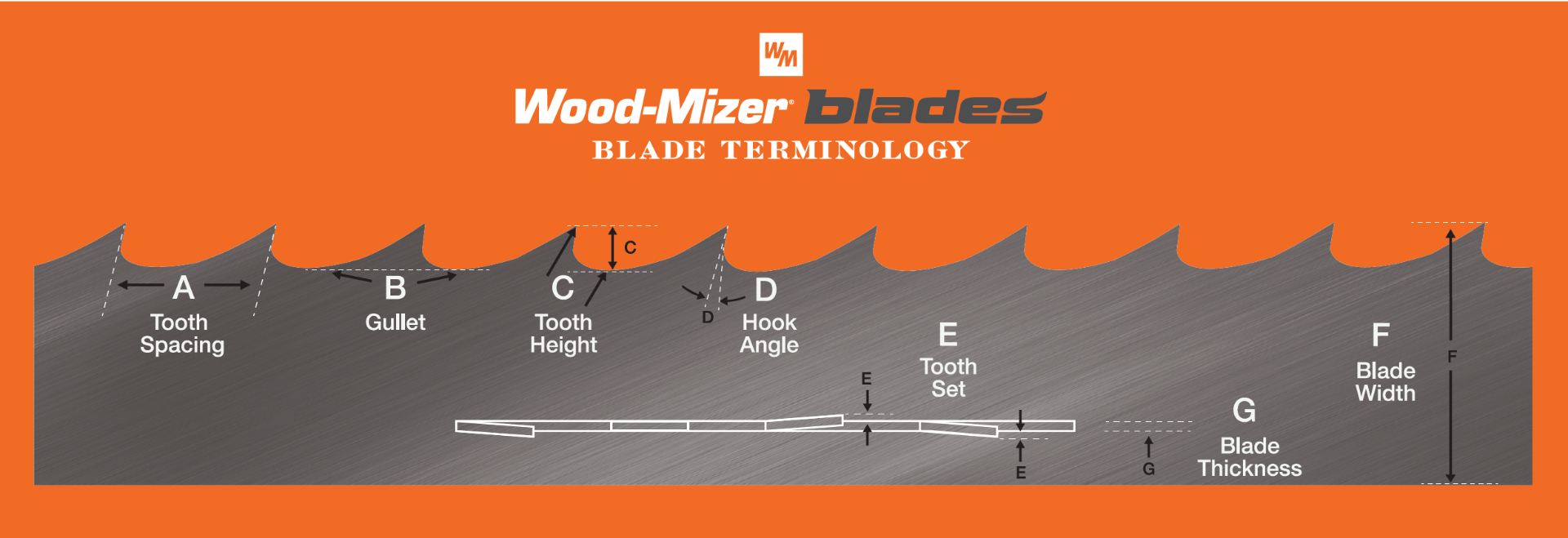

A. Tooth Spacing is the distance between each tooth from one tip to another. Shorter tooth spacing (1/2", 5/8", 3/4", and 7/8") is generally used for low horsepower sawing (24HP or less), secondary processing, and resawing, while wider tooth spacing (1” and 1-1/4”) is ideal for high production, high horsepower (25HP or more) operations.

B. Gullet is the area between teeth that captures and removes sawdust while providing strength in the tooth. The tooth height must be tall enough to allow the gullet to carry out sawdust from the cut.

C. Tooth Height is the distance from the lowest point of the gullet to the highest tip of the tooth. Taller teeth (4°, 7°, and Turbo 7° hook angle) provide more performance in higher horsepower (25HP or more) with increased sawdust removal. Shorter teeth (9° and 10° hook angle) are better for lower horsepower (24HP or less), small log diameter sawing, resawing, and secondary processing.

D. Hook Angle is the number of degrees that the tooth face leans forward of 90 degrees. The hook angle should be chosen based on the type of wood you are sawing.

- 4° - Lowest hook angle for sawing frozen, dense hardwoods and knotty softwoods.

- 7° - Solid, all-around profile with a good gullet capacity for higher horsepower (25HP or more) sawing in hardwoods.

- Turbo 7 - Only available from Wood-Mizer, this high performing profile with an aggressive 39° back angle is engineered specifically for extreme and exotic hardwoods when sawing with higher horsepower (25HP or more) equipment.

- Turbo 747 – Only available from Wood-Mizer, this profile is compatible with all horsepower levels and features a deeper capacity gullet for increased sawdust removal, extreme 47° back angle for faster sawing speeds, and sharp penetrating points for increased sawing accuracy.

- 9° - Ideal blade for lower horsepower (24HP or less) sawing frozen wood, hardwood, and small diameter logs.

- 10° - Very popular all-purpose blade for all horsepower levels sawing mixed hardwoods such as red oak, cherry, walnut, soft maple, and poplar.

- Vortex™ - Only available from Wood-Mizer, this unique dust-removal profile has more gullet capacity to remove sawdust from the board.

E. Tooth Set is the distance the tooth is bent beyond the body or raker tooth of the blade. Tooth set clears a path in the wood for the body of the blade which is measured by kerf or the total amount of wood removed by the blade with each pass. Wood-Mizer thin kerf blades remove less than 1/10” which produces about 20% more boards per log than circle mills or chainsaws.

F. Blade Width is the distance between the tip and base of the blade. Wider blades (1-1/2" to 2") are designed for higher horsepower (25HP or more) sawmills, provide a faster feed rate, and are able to be resharpened more. Narrow blades (1- 1/4" to 1-1/2") are for lower horsepower sawmills (24HP or less) and more difficult sawing.

G. Blade Thickness is the thickness of the blade. Thicker blades (.045", .050", .055") provide faster feed rates and better cutting performance in difficult sawing conditions such as knotty, frozen, dry or extremely hard material, but requires higher horsepower (25HP or more). Thinner blades (.035", .038", .042") provide longer flex life with lower horsepower sawmills (24HP or less) where production or speed is not a primary factor.

Shop 158" sawmill bandsaw blades compatible with:

- Wood-Mizer LT15START, LT15, LT20, LT25/27, LT28, LT30, LT35, LT40, LT50 portable sawmills

- Wood-Mizer HR120, HR130, HR300, HR500 band resaws

- Baker Model A, Model AB, Model B, Model C, Model PAQ, Model II PAQ band resaws

- Timberking 1200 portable sawmills

- Woodland Mills HM130MAX portable sawmills

Shop 158" sawmill bandsaw blades compatible with:

- Wood-Mizer LT15START, LT15, LT20, LT25/27, LT28, LT30, LT35, LT40, LT50 portable sawmills

- Wood-Mizer HR120, HR130, HR300, HR500 band resaws

- Baker Model A, Model AB, Model B, Model C, Model PAQ, Model II PAQ band resaws

- Timberking 1200 portable sawmills

- Woodland Mills HM130MAX portable sawmills

Sawmill Blade Material Selection Guide

MOST AFFORDABLE

SilverTIP Carbon Steel

- Most common and affordable carbon steel material

- Economical sawing or for high volume sawmills and resaws

- Resharpen with CBN grinding wheel

MOST POPULAR

DoubleHARD High-Alloy Steel

- Tough, non-chip high-alloy steel material with induction hardened teeth

- All-purpose sawing of softwoods, hardwoods, knotty woods, and frozen woods

- Up to double the blade life compared to carbon steel sawmill blades

- Durable sawmill blade with multiple resharpenings using CBN grinding wheel

SPECIALTY

BiMETAL Two-Piece Steel

- Two-piece high-alloy steel body with high-speed steel (HSS) tooth tip

- Specialty sawing for reclaimed beams or kiln dried lumber and in industrial sawmilling environments

- Up to double the sharp life compared to carbon steel sawmill blades

- Durable sawmill blade with multiple resharpenings using CBN grinding wheel

SPECIALTY

RazorTIP Carbide Steel

- Very hard triple chip tooth configuration with a carbide-tipped raker tooth

- Specialty sawing of tropical hardwoods, reclaimed beams, kiln dried lumber, engineered wood, and more abrasive materials

- Harder teeth than high-alloy blades and up to triple the sharp life compared to carbon steel sawmill blades

- Durable sawmill blade with multiple resharpenings using diamond grinding wheel

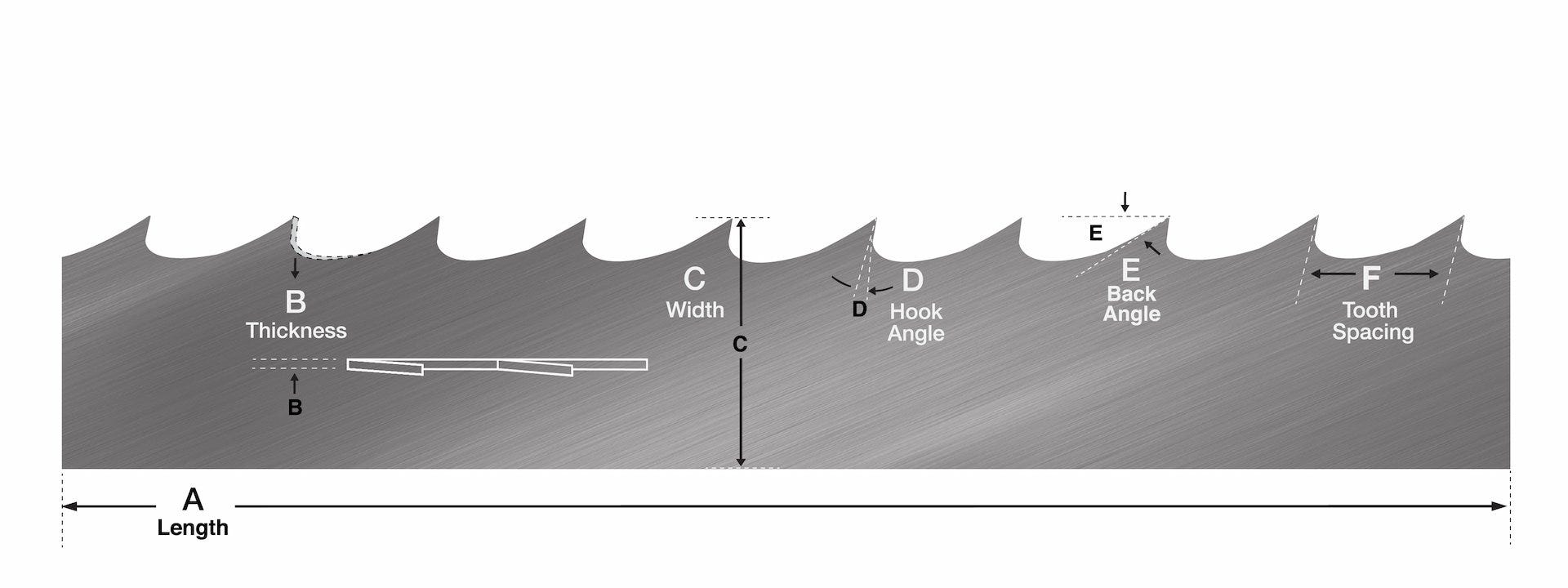

Sawmill Blade Thickness x Width Selection Guide

Thickness (B) is the thickness of the body of the sawmill blade without including tooth set.

- Thicker blades (.045", .050", .055") provide faster feed rates and better cutting performance in difficult sawing conditions such as knotty, frozen, dry or extremely hard material, but require higher horsepower (25HP or more).

- Thinner blades (.035", .038", .042") provide longer flex life with lower horsepower (24HP or less) sawmills where production or speed is not a primary factor.

Width (C) is the distance between the tip and base of the sawmill blade.

- Wider blades (1-1/2” to 2”) are for higher horsepower (25HP or more) sawmills and a faster feed rate.

- Narrow blades (1” to 1-1/2”) are for lower horsepower (24HP or less) sawmills and more difficult sawing.

Sawmill Blade Hook Angle Selection Guide

Hook angle (D) is the number of degrees that the tooth face leans forward of 90 degrees.

Back angle (E) is the number of degrees that the backside of the tooth leans backward of 90 degrees.

The hook angle and back angle of a sawmill blade should be chosen based on the type of wood you are sawing and what type of equipment you are sawing with.

- 10° Sawmill Blades - Most popular and versatile all-purpose hook angle with a 30° back angle for sawing softwoods, medium hardwoods, and hardwoods including birch, beech, red oak, cherry, walnut, soft maple, pine and poplar.

- 9° Sawmill Blades - Ideal hook angle with a 29° back angle for lower horsepower (24HP or less) sawing in frozen wood, hardwood, and small diameter logs.

- Turbo 747 Sawmill Blades - Only available from Wood-Mizer, this popular hook angle with an extreme 47° back angle for faster sawing speeds is compatible with all horsepower levels and features a deeper gullet capacity for increased sawdust removal and sharp penetrating points for increased accuracy when sawing softwoods and hardwoods.

- Turbo 7° Sawmill Blades - Only available from Wood-Mizer, this high-performing hook angle with an aggressive 39° back angle is designed for higher horsepower (25HP or more) and higher feed rate sawing in extreme hardwoods including white oak, hickory, ash, hard maple and more.

- 7° Sawmill Blades - Solid, all-around hook angle with a 34° back angle and additional gullet capacity for higher horsepower (25HP or more) sawing in hardwoods.

- 4° Sawmill Blades - Lowest hook angle with a 32° back angle for sawing very hard, frozen, or partly frozen hardwoods with high density including acacia, beech, oak, hornbeam, and ash.

- 12° Sawmill Blades - Ideal hook angle with a 28° back angle for sawing softwoods and resawing.

- Vortex™ Sawmill Blades - Only available from Wood-Mizer, this unique dust-removal sawmill blade has more gullet capacity to remove sawdust from the board.

Sawmill Blade Tooth Spacing Selection Guide

Tooth spacing (F) is the distance between each tooth from one tip to another. The pitch of a sawmill blade is also used in reference to tooth spacing as the number of teeth per inch or TPI on a bandsaw blade.

- Shorter tooth spacing (1/2”, 5/8”, 3/4”) is used for low horsepower (24HP or less) sawing and resaw purposes, or secondary processing.

- Most common tooth spacing (7/8") is for all-purpose sawing and recommended for most portable sawmill equipment.

- Wider tooth spacing (1” and 1-1/4”) is for higher horsepower (25HP or more) sawmills and high production.

Unmatched Performance

At the heart of every great sawmill and resaw are the industry’s best sawmill blades. To ensure the ultimate sawmill blade performance across the board, Wood-Mizer designs and manufactures our own blades and is the only portable sawmill equipment manufacturer that does so.

Unmatched Selection

From sawing green softwoods to abrasive hardwoods, Wood-Mizer offers a wide selection of sawmill bandsaw blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and material for any type of sawing or resawing application.

Unmatched Quality

Each Wood-Mizer sawmill blade tooth is precisely set by computer-controlled equipment and completely profile ground tip to tip using super abrasive CBN grinding technology. From the selection of raw steel to performing more than 100 tests and inspections through the final grind, we are dedicated to providing the highest quality sawmill blades on the market.

Unmatched Compatibility

Wood-Mizer gives you more choices by manufacturing sawmill blades for Wood-Mizer, Baker, Cooks, Hud-Son, Norwood, Timberking, Timbery, Woodland Mills, and more band sawmills and resaws!