Former Electrician Builds Dream Home in British Columbia

By Chase Warner, Wood-Mizer

Working as an electrician on high end custom homes in Oregon for more than a decade, Nathan Shewchuk realized there must be more to life. “I was tired of the city and wanted nothing more than to move into a remote part of Canada and build a house, so I did,” said Nathan. With eight years of hard work and dedication, along with a few helpers and a Wood-Mizer portable sawmill, Nathan accomplished his lifelong dream of building his own home.

Nathan’s story begins in 2007 when he purchased land in British Columbia in order to start building his home. Nathan found that he could either buy lumber and transport it to his remote location or produce lumber himself utilizing local timber from his land.“I looked into a few different sawmills but found nothing compared to Wood-Mizer,” said Nathan. “I thought that this was the only way to go, what a handy tool.” Without any previous sawing experience, Nathan purchased an LT40 Hydraulic Portable Sawmill and was set to continue his new life chapter. “I just went in headfirst and figured it out,” he said. “I spent basically my whole life in the trades, framing, and finish carpentry, so [building and woodworking] wasn’t anything new to me.”

Nathan wanted 100% of the wood in his home to be sawed on his Wood-Mizer sawmill, so that meant lots of trips to the kiln and many years of drying lumber. “It took eight years, that’s from clearing the property to the last nail,” he said. The first year of construction, Nathan completed the roof and milled all the cedar materials needed for the windows and doors of his home. With help from his neighbor and master finish carpenter, Kit, the windows and doors were completed and Nathan was able to move into his home for the first time that Fall. “The Wood-Mizer was a wonderful tool, it was perfect for the job,” he said.

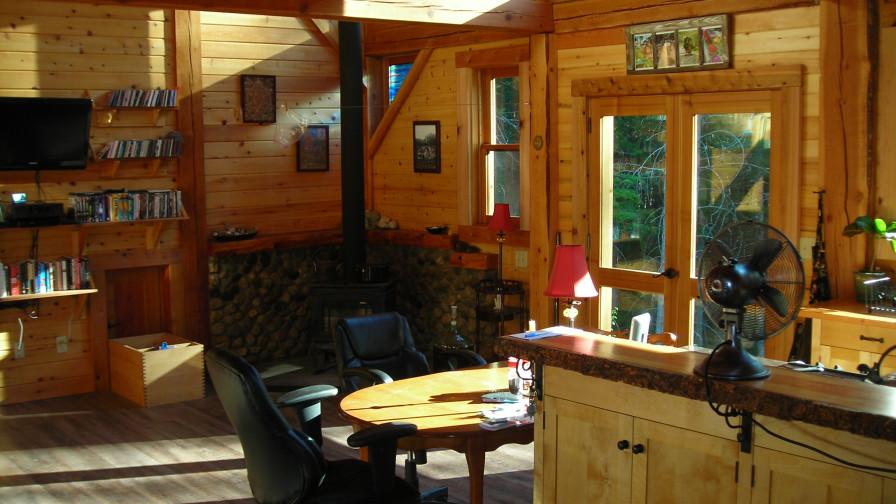

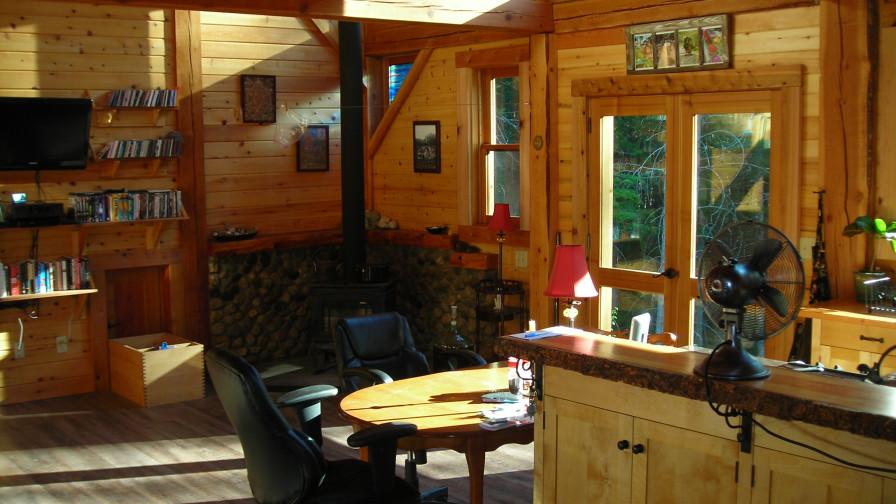

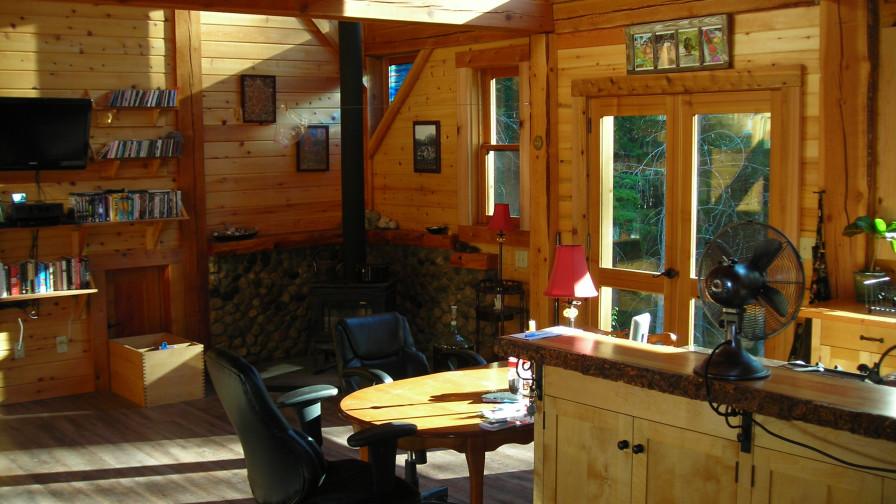

Over the next few years, Nathan milled birch and douglas fir needed for the rest of the interior of his home and worked on all the finishing woodwork needed for the windows. He also built a rock fireplace and shower and milled all the tongue and groove wood for the walls and ceiling. After eight years of hard work building and sawing 100% of the 22,000 board feet of douglas fir, larch, birch and cedar on his LT40 Hydraulic Portable Sawmill, Nathan had finally finished his dream home and woodworking shop. With help from many friends and neighbors, Nathan completed his home from the ground up just how he had dreamed. “My neighbor, Kit did all the cabinets, doors and finish carpentry and my friend Doug was there hand-in-hand for carpentry work and many brainstorming nights,” said Nathan. “Many people helped along the way and I am very fortunate to have a lot of good friends.”

Nathan estimates he saved between $70,000 and $80,000 by sawing his own lumber for his home that features a 1,200-square-foot living space, 1,500-square-foot woodworking shop, and 500-square-foot deck. “I get an overwhelming response to my home,” said Nathan. “All in all, I had the time of my life and owe many people for their knowledge and skills. This would not have happened without that.” As for the future, Nathan can’t wait to get onto his next project.

Working as an electrician on high end custom homes in Oregon for more than a decade, Nathan Shewchuk realized there must be more to life. “I was tired of the city and wanted nothing more than to move into a remote part of Canada and build a house, so I did,” said Nathan. With eight years of hard work and dedication, along with a few helpers and a Wood-Mizer portable sawmill, Nathan accomplished his lifelong dream of building his own home.

Nathan’s story begins in 2007 when he purchased land in British Columbia in order to start building his home. Nathan found that he could either buy lumber and transport it to his remote location or produce lumber himself utilizing local timber from his land.“I looked into a few different sawmills but found nothing compared to Wood-Mizer,” said Nathan. “I thought that this was the only way to go, what a handy tool.” Without any previous sawing experience, Nathan purchased an LT40 Hydraulic Portable Sawmill and was set to continue his new life chapter. “I just went in headfirst and figured it out,” he said. “I spent basically my whole life in the trades, framing, and finish carpentry, so [building and woodworking] wasn’t anything new to me.”

Nathan wanted 100% of the wood in his home to be sawed on his Wood-Mizer sawmill, so that meant lots of trips to the kiln and many years of drying lumber. “It took eight years, that’s from clearing the property to the last nail,” he said. The first year of construction, Nathan completed the roof and milled all the cedar materials needed for the windows and doors of his home. With help from his neighbor and master finish carpenter, Kit, the windows and doors were completed and Nathan was able to move into his home for the first time that Fall. “The Wood-Mizer was a wonderful tool, it was perfect for the job,” he said.

Over the next few years, Nathan milled birch and douglas fir needed for the rest of the interior of his home and worked on all the finishing woodwork needed for the windows. He also built a rock fireplace and shower and milled all the tongue and groove wood for the walls and ceiling. After eight years of hard work building and sawing 100% of the 22,000 board feet of douglas fir, larch, birch and cedar on his LT40 Hydraulic Portable Sawmill, Nathan had finally finished his dream home and woodworking shop. With help from many friends and neighbors, Nathan completed his home from the ground up just how he had dreamed. “My neighbor, Kit did all the cabinets, doors and finish carpentry and my friend Doug was there hand-in-hand for carpentry work and many brainstorming nights,” said Nathan. “Many people helped along the way and I am very fortunate to have a lot of good friends.”

Nathan estimates he saved between $70,000 and $80,000 by sawing his own lumber for his home that features a 1,200-square-foot living space, 1,500-square-foot woodworking shop, and 500-square-foot deck. “I get an overwhelming response to my home,” said Nathan. “All in all, I had the time of my life and owe many people for their knowledge and skills. This would not have happened without that.” As for the future, Nathan can’t wait to get onto his next project.